Outdoor running track installation basic process

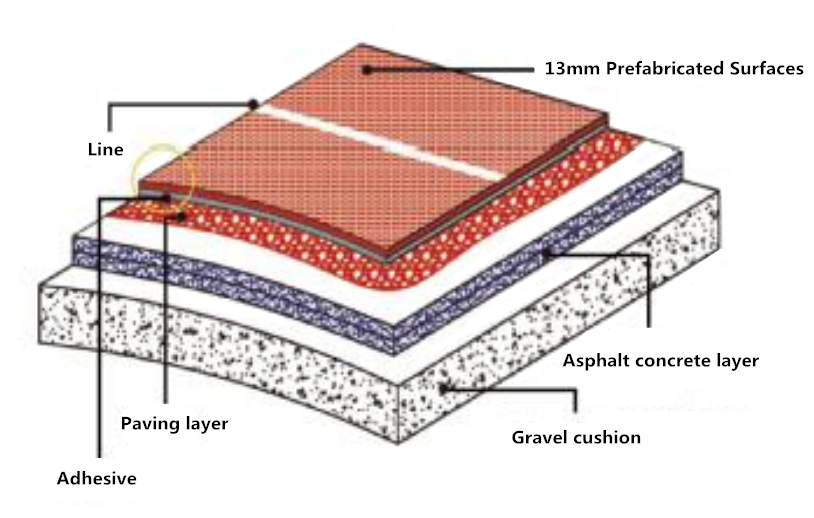

Prefabricated surface installation basic process

1. Prime soil compaction:

Tamped density of 95%;

Detection methods:

Reinforce the extent determined by the on-site sample testing,

Tamping degree: Modified Platts method 95-98%

2.Lime soil base:

Lime content: 12%;

Layer thickness: 200mm;

Detection methods:

Note:

According to the groundwater level and regional severe cold conditions, the material composition and thickness of the foundation layer can be determined according to local conditions. The structure of the Northeast and South will be different.

3.Graded gravel cushion:

The coarse-graded gravel particle size: 15-25mm,

Thickness of coarse-graded layer: 100mm;

Fine-graded crushed stone particle size: 5-15mm,

Thickness of fine-graded layer: 100mm;

Compaction and leveling with rollers over 8 tons;

4.Adhesive layer:

Spray asphalt and oil as the glue layer;

Adhesive layer thickness: determined according to actual conditions;

5.Coarse asphalt concrete layer:

Type of asphalt concrete: AC-15I;

The asphalt content in the mixture: more than 4-6% (by weight);

Crushed stone used: solid, angular stones, do not use shale;

Layer thickness: 40mm.

6.Fine asphalt concrete layer:

Type of asphalt concrete: AC-10I;

Gravel particle size: 1-10mm (70% of the particle size: 1-5mm);

The paving process must use mechanical paving;

Surface void ratio:

The content of asphalt in the mixture: more than 4-6% (in terms of weight ratio);

Crushed stones used: solid, angular stones, shale cannot be used;

Layer thickness: 30mm.

Categories

- Stadium Athletics Track

- Artificial Grass

- College | University | School Rubber Running Track

- Pickleball Court Flooring

- Kindergarten Synthetic Playing Surfaces

- Sport Court Surface

- Basketball Court Flooring

- Tennis Court Flooring

- Rubber Gym Flooring

- Park Jogging Track Rubber Flooring

- Massage Mat

- Construction Tools

Keep in touch

Get Insider Information About Exclusive Offers, Events And More!